Can someone who has lost an ear in an accident ever look whole again? This article explains how we can now regrow and even “print” new ears.

Having ears is not something many of us think about; we just have them and that’s the end of it. But when accidents or disease happen, a missing ear can be unbelievably disfiguring as well as negatively impacting our hearing. The congenital condition of microtia, when a person is born without an outer ear, has spearheaded most research to date.

What is truly astounding is that ears can actually be regrown; regrown exactly like your original ear. But if this is not an option for you because of complicated medical reasons, it may be possible to just “print “you an ear with a 3D printer. How amazing is that?

How can an ear be regrown?

This is the result of the miracle of tissue engineering. Not only can ears be regrown, but soon cartilage, livers, kidneys and many “replacement parts” will be able to be generated in the lab for your use. There are at least two ways an ear can be regrown; on the back of a mouse, and on the patient’s own forearm. Deciding which way depends on the condition of the skin of the patient; whether it is healthy enough to grow a replacement ear.

The way it works is a “scaffold” is built out of a biodegradable material. Then cartilage cells are “planted” in the skin about 3 millimeters apart. What is great about the scaffold is that it can be shaped into any form needed, so ears can be customized. The scaffold can be “planted” on the back of a mouse (without harming the mouse) or on the forearm of a patient. If the ear is grown on a mouse, the mouse has to have no immune system so it does not reject the ear. If the ear is grown on a patient’s forearm, there is no worry of rejection since the cells come from the patient themselves. When the ear is ready, it is surgically removed and attached over the patient’s ear canal.

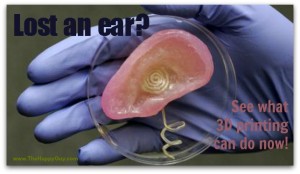

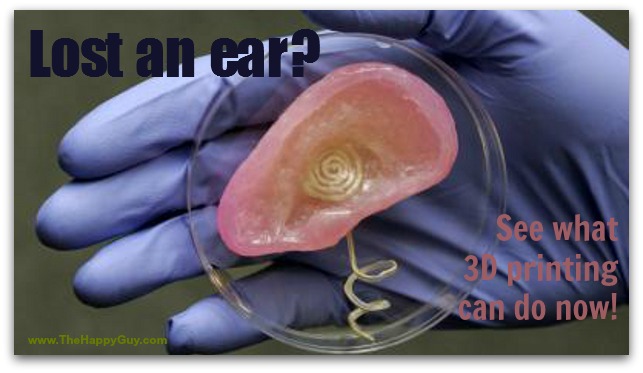

How are ears “printed” with a 3D printer?

First, a digitized 3D image of a human ear is taken and converted to a digitized solid ear by using a 3D printer. From this, a mould is made and filled with a gel of living cartilage cells. In about 3 months, the ear is completed, removed from the mould and is then surgically placed on the patient.

What about using rib cage cartilage to make a new ear?

When a patient’s best option is to use cartilage from their own body, this is a possibility. The procedure takes a bit longer, but the results are cosmetically better overall. Cartilage is taken from the ribcage of a patient, shaped in the basic form of an ear and implanted under the skin of the forearm. It is left there for about 4 months so the skin can grow over it. Then, it is surgically removed and placed over the ear canal. Gradually, over many months and surgeries, The ear is matched to the other ear.

What other ways to replace ears are being researched?

Bioengineers in Massachusetts are experimenting with living tissue from other animals besides human. They have built an artificial human ear by putting together tissues from cows and sheep, and then placing the tissues around a wire frame that allows the tissues to grow into the correct shape of an ear. The wire used is titanium and can be shaped with much detail. The ear is then placed on a mouse to grow until it can be attached to a patient’s head.

Bioengineering may be only in its infancy, but already look at the amazing things it can do. Imagine what will be able to be accomplished in 10 or 20 years!